February 4, 2012

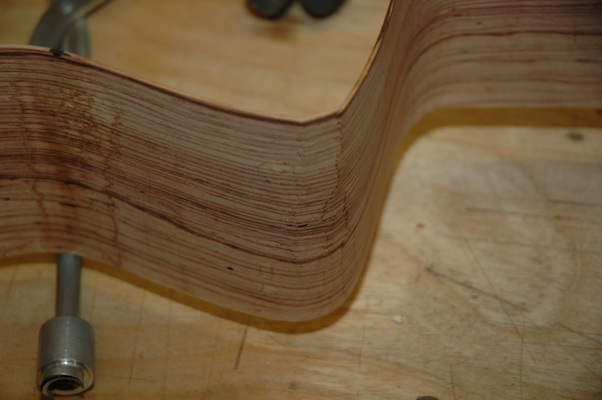

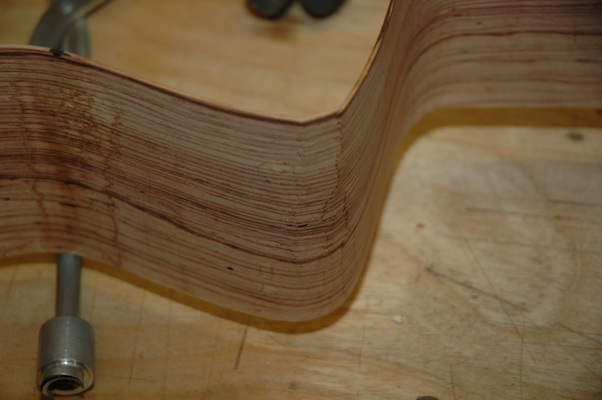

As mentioned previously, the cutaway bend probably cracked. I let the bent sides sit in the bender overnight so as to allow the bends to settle, then opened the bender carefully.

The underside of the sandwich was held in place with a bit of wire to keep it from springing up and pushing against the bent side. After removing from the machine, the crack was evident.

Two cracks, on either side of the outer bend can be repaired with CA glue, then the bend can be rounded on the hand bending heater before attaching to the guitar top. This piece is salvageable and will be fine. After aggressive sanding and fairing, there should be no evidence of the crack. I might consider gluing a small spruce caul into the inside of the bend to provide stability.

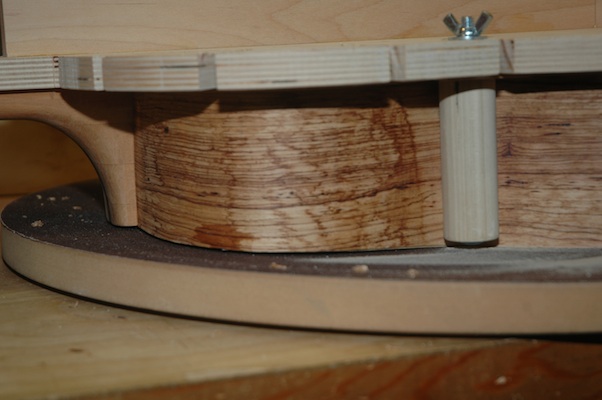

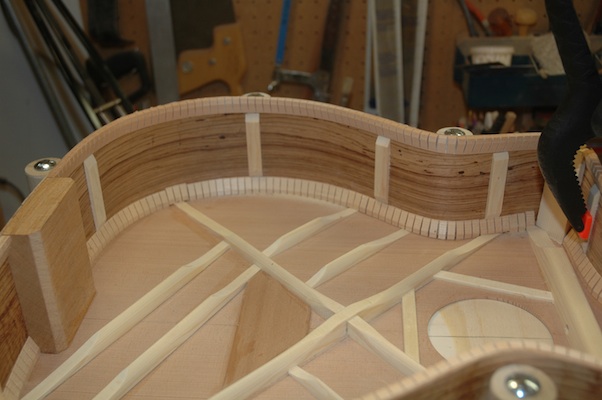

I began installing the non-cutaway side. First I increased the bends on the hand bender, determined the position of the cut for each end to shorten the side piece, applied glue to the butt block, neck slot and joint between the side and the top. It slipped into the workboard easily, and followed the trace of the joint nicely, so I was able, on the first pass, to clamp down.