Guitar 903 – Box trimming, neck shaping

December 11, 2010

Devin is putting the finishing touches on shaping the neck. The heel and neck to transition still need working, and the headstock is in need of thinning to accept the newly arrived tuning machines.

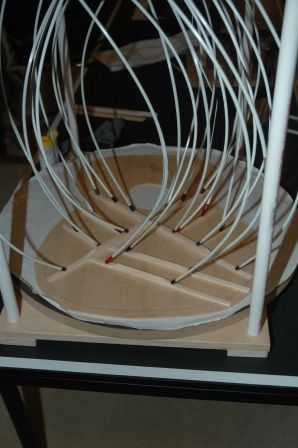

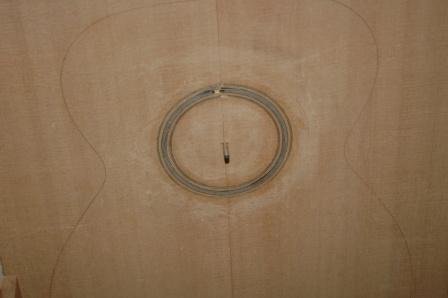

The box plates have been installed, and after removing from the go-bar clamp, the excess scarf was removed with a router.

Devin’s pretty happy with the results. He took some time to scrape the back with a cabinet scraper. After removing minor burn streaks left by the drum thicknesser, new colors and flame were revealed.

This is one really nice piece of walnut.

We experimented with the Wagner Safe-T-Planer, a drill press inserted planer that some luthier’s have claimed success with. We were able to take 1/8″ thick stock and plane it down to around .090″, the desired thickness for binding. We were able to get 4 reasonable binding strips out of the band saw, and are crossing our fingers that this will bend up nicely without cracking.

The issue is with the wood. We are using purple heart, which I haven’t seen used before, and my suspicion is that it doesn’t bend well. We may have to rethink the binding after it comes out of the bending machine.