Guitar 904 – Makin’ the box

May 24, 2009

My good friend Bryan is dropping by this afternoon. This morning did some irrigation investigation and earned a few moments in the shop.

Since deciding on an unadorned headstock (i.e., sans logo), I was conniving a location for the sMg. End graft seemed to be the most interesting opportunity. I removed the sides from the mold and notched out the area for the tapered end graft, glued down with BWB purfling then scraped down to approximate depth.

Cool eh? Here’s another look, with my hand in the photo for perspective (really, my hand wanted to be photographed).

I used a prefab neck block for a dreadnought which was too tall AND had inappropriately spaced pre drilled holes. Located new hole for truss rod access and second neck bolt hole. Drilled these out before assembling back and top as to avoid chipout on the neck block.

I consider the extra hole a pressure relief valve. It has to have a purpose, and now it does.

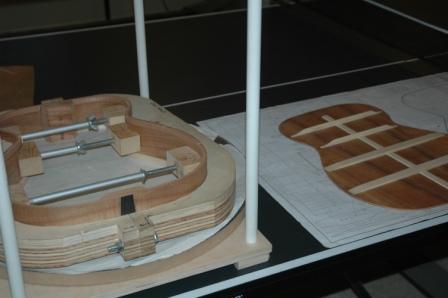

I continued to trim top bracing and got them down to the point where I could locate and route out the upper bout brace area that runs into the kerf. This allowed me to assemble the back on to the sides. While the glue dries, I can proceed with fine tuning the top braces.

Parts are set out in the go-bar clamp in preparation for gluing.

Abstract onion sculpture.

Stephen on 25 May 2009 at 10:02 am #

Wow, looking like good progress is being made!