Guitar 1001 – Rosette construction

September 8, 2008

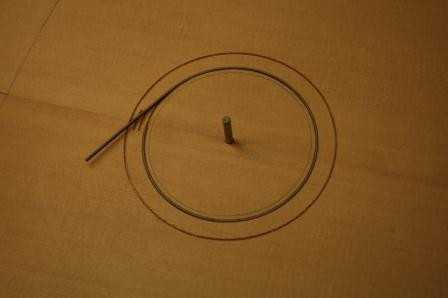

Rosette construction for the Koa Dreadnought begins with locating the center of the soundhole, drilling a 3/16″ hole then mounting on a center pin on a workboard on the workbench. This pin matches a dremel circle cutting jig. A downcut end mill is used in the dremel to cut channels for the rosette purfling.

First and second pass is for the inside and outside rings with a 3/32″ end mill.

After the channels are routed, the purfling is installed with white glue. Each purf strip is pressed in and the glue squeeze out is cleaned up.

Before routing the center channel, the installed purf is allowed to dry and then scraped down to plate surface level.

The center channel width is 2 purfs plus a .063″ center teflon strip. The teflon strip is the same width as the Abalam shell which will go between the inside and outside purf in the center channel. The channel is prepped with white glue and the purf/teflon/purf sandwich is pressed into the center channel.

After drying, the teflon strip is pulled out, the cavity is cleaned up to remove any dried glue clumps, then curved Abalam strips are pressed into the cavity. CA glue is flooded onto the Abalam. Several applications of CA are needed to fill the channel before the rosette rings are ready to be scraped flush and sanded. Only after the rings are flush will the soundhole be cut out.