Guitar 1001 – Ready for Delivery

May 14, 2011

What with going to school and learning to teach, and actually then teaching, I have seen serious erosion of my time available to devote to building. So it has been almost a year in elapsed time since I started this Koa Dreadnought.

Today, it is finished. I have contacted the client to arrange pickup. He can take his time, as I will get to play it more the longer he waits. It’s hard to give up these guitars, I want to keep them all, but I have too many anyway to begin with.

Today I crept down into the shop, trying not to wake my sleeping son who was crashed in the basement after his night out at the prom. Dress the frets, polish the saddle and nut, oil the fretboard, install the pickguard, put the strings back on, whoops, clean out the ort from inside the box, install the label, then put the strings back on. Tune it, play it, smile, weep, move on.

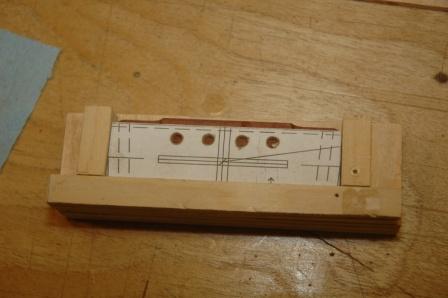

I like this little rosewood veneer backing.