Jigs and Workboards

June 20, 2011

Working on jigs and workboards today. I’ve decided to create a neck shaping jig, simply a platform to clamp the neck to so I can stick it in the vise and have clearance to shape the backside of the neck and heel.

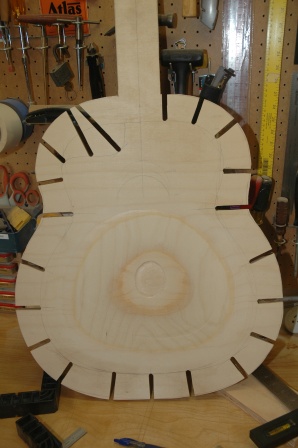

I’ve continued to fine tune the Hybrid workboard. First step was to hollow out the surface to a 28′ radius to compensate for the bridge area bulge. I marked a few elevation lines as guides.

I used a router with a rounded bit set to 4mm depth for the center, then dropping 1mm for each of the next elevation lines until the final shelf was routed to a depth of 1mm.

I used the table saw to complete the slots from the edges in toward the center where the dowel clamps go.

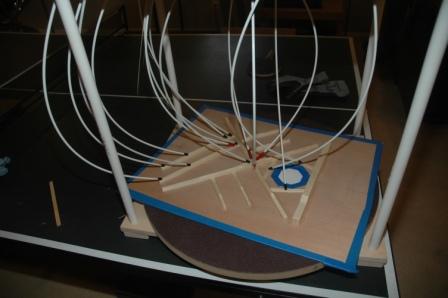

Finally, a tripod stand was mounted to the back for resting on the workbench or clamping into the vise.