Guitar 901, 902 and 904 have been cured: Praise God Almighty

August 31, 2009

It’s been two weeks since I applied the final coats of lacquer on three guitars. They have sat long enough for the lacquer to be ready for final sanding and buffing.

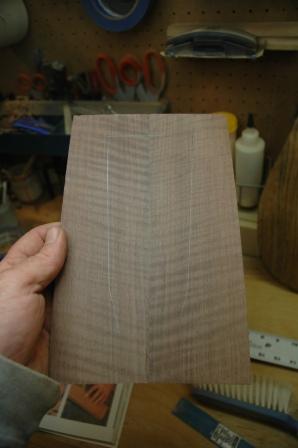

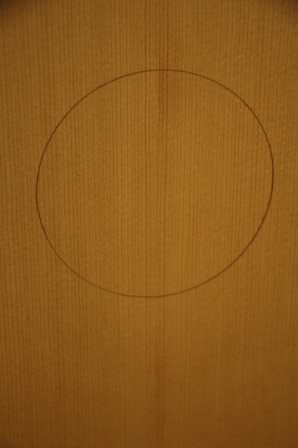

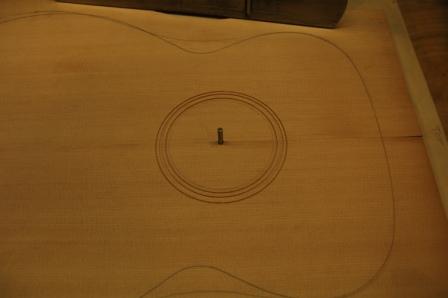

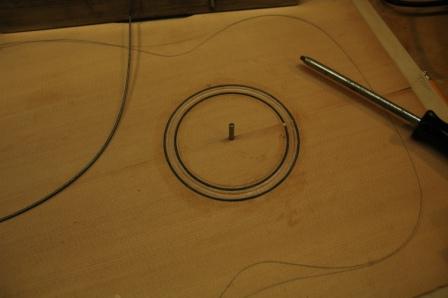

The resonator:

I’m going to tackle this guy first because I’m so interested in playing it as soon as possible.

Finally, Carol’s and Beth’s guitars, very different, but quite stunning. They’ll look great, and I’m anticipating good quality guitar like sounds coming from them once they’re strung up.

Even though these both are Koa guitars, they have very striking differences.