Resumption

October 22, 2017

I have officially resumed building. I retired in June from teaching and have ministering to the health care and benefits schlmazel that was necessary to make the transition from employment. Now that I am enrolled in Medicare and supplemental insurance, I can get care for any workshop mishaps with sharp tools (both power and hand).

I have a parlor, an OM, a ukelele, and a Macaferri style guitar in the final stages of production. I’m also mentoring my son, William, on the construction of a Stew-Mac faux Stratocaster.

The parlor (aka 1201) and the OM (aka 1202) have experienced recent neck shaping and fretboard binding. Most of my recent efforts have been relocating the materials, tools and jigs I use. Mostly an effort in remembering where everything lives (which bin, which cupboard, which whatever?). Example: Last week I remember stumbling on a headstock template which I could use for 1202, yet, where is it? I put things down, make a mental note, then have great difficulty finding my mental note in my mental cabinet and subsequently spend time swearing at myself.

The upcomming challenge is to reset the neck for 1202 to remove the 14th fret bulge. This will require careful chisel work. I must confess my chisel work is still rudimentary; not at the skill level to which I aspire.

William and his Stew-Mac Stratocaster

1202: Rosewood OM with Vine fretboard inlay

Rosewood binding on fretboard for 1201

Ivroid binding for fretboard of 1202.

Update: Uke Parlor Hybrid

August 26, 2012

Yeah, Guitar Camp was awesome, and now I’m home counting the days before I start back teaching. I took a uke and an OM to camp, and as usual garnered a lot of interest from fellow campers who claim they “must have one”. On the last day of camp advice is given to those of us returning to the non-camp world. One bit of proper advice was, “Wait three weeks before accepting a proposal of marriage from a fellow camper.” Same goes for committing to a new uke or guitar.

I’ve resumed where I left off before camp. The Hybrid for Jim has a first coat of pore filler (an epoxy resin) and is lined up for the spray booth.

I’ve installed all binding on the Myrtle Parlor.

I then did what all good builders should do, I burnished my cabinet scraper. Ah, what a difference! Several smooth strokes across the top, and the binding is trimmed flush with the top.

I’m so in love with my first uke. I played it at camp and caught the bug. The uke I’m working on now is really for me (so I’m differently motivated). The top is braced, the tonebars are installed and the neck and top have been joined.

The neck has been stabilized with a graphite rod which lives under the mahogany strip in the center of the neck.

First the bracing and bridge plate were installed.

Then the tone bars.

Finally, the neck and top can be joined.

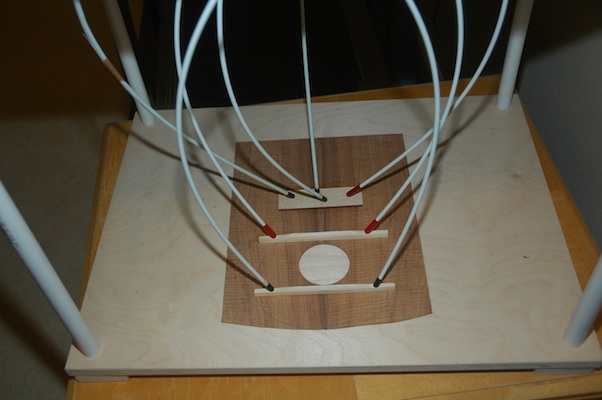

Guitar 1202 and 1203 plus Uke 1201

July 3, 2012

Did a little neck work today on Uke 1201. I used the table saw to cut the spanish heel slots and to nibble away at the heel profile.

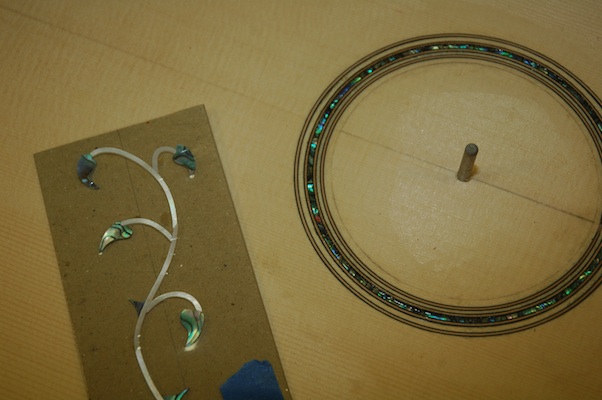

Also for both 1202 and 1203, I installed the rosettes. The OM has a teflon strip which is removed before pressing in the abalam. The parlor has a pre-manufactured herringbone.

The abalam is pressed into the gap left by the teflon then flooded with CA glue. The shell shown below will be added to the headstock to mirror what’s on the fretboard.

Before routing out the channels for the headstock shell, the plate has been glued to the headstock.

Uke 1101 – Koa Tenor, Neck Construction

April 10, 2011

It’s time to take on the new uke. The first uke is curing, and will be completed in about two weeks. I’ve blocked up the neck, and sketched in the profile, taper, and heel cutouts.

This pic shows the cutouts for the side insertion and the heel shaped with a nibbling jig on the table saw.

The heel block portion which is inside the uke has been shaped and trimmed. The headstock and neck have been trimmed to approximate thickness. Next step will be to taper.

Guitar 1002 – Neck Heel Profiled

January 23, 2011

The heel profile and neck thickness have been cut using a band saw.

Next, a slot will be cut at the 14th fret for the sides to be inserted into. Then, the neck will be tapered to dimensions of a steel string neck profile.

Guitar 1002 – Headstock Slotting

December 26, 2010

Located slot position on headstock and drilled out holes (smaller than 1/2″) in preparation for head slotting.

The slot opening will be 1/2″. By rasping out the material between the drilled holes, I’ll be able to create a flattened opening.

Guitar 1001 – Neck Joint Finished

December 26, 2010

Today, I finished fine fitting the neck to body joint and installed the neck bolt inserts.

After shaving the inside of the neck where it meets the body, and sanding to ensure a flush fit between neck heel and body, I marked the location for the neck inserts and drilled two 10mm holes.

The sides of the tenon are clamped to prevent cracking when drilling and installing the inserts. After the inserts are installed, CA glue is drizzled to secure the inserts and strenghten the tenon. The truss rod is also inserted.

The neck is bolted to the guitar to check fit before installing the fretboard. Later today I will further reduce the thickness of the fretboard, install frets then glue the fretboard to the neck.

Tomorrow, Steve, my customer, will drop by to check progress. The neck is roughly finished, and Steve can provide input as to final neck shape and thickness.