Guitar 906 – Routing the fretboard and headstock

November 30, 2009

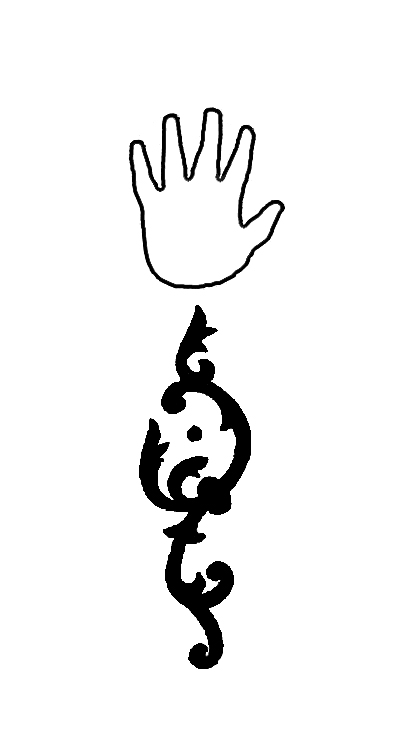

I have several internet orders in transit for the replacement of 1/32″ end mills which I use (and break) for the fine detail fretboard and headstock routing of inlay channels. Once received I will be able to finish the routing, then inlay the “vine and thorn” shell which was chosen for this guitar.

I was able to complete the bulk of the routing using a 1/16″ end mill, but will need to use the 1/32″ for sharp ends of the thorns.

The next picture is a closer look, where you can see the unfinished thorns and leaves.

I worked very carefully on the koa headstock (after practicing on the ebony fretboard) as any gaps between the shell and the koa are hard to hide. The ebony is more forgiving as the black epoxy adhesive dries to be virtually identical to the ebony, thus invisible. I use clear epoxy mixed with koa powder (from sanding) and will be nearly the color of the headstock but less invisible.

The following shows what it will look like with the shell inlayed and the remaining work with the 1/32″ end mill to fully open the channels for the leaves and thorns.