Guitar 1202 – Box On Garth

January 3, 2013

Good news from LMI: KTM9 water based lacquer has shipped from the manufacturer. Availability to me starts January 9th.

Did some packing of the uke after fully prepping it for lacquer finish. I’ve sent it off to Athens, GA for finishing.

The box for the OM aka “Bob” is closed in. I did neglect to install the electronics, but justified my mistake by saying that I need practice installing these after the fact anyway, so we all say.

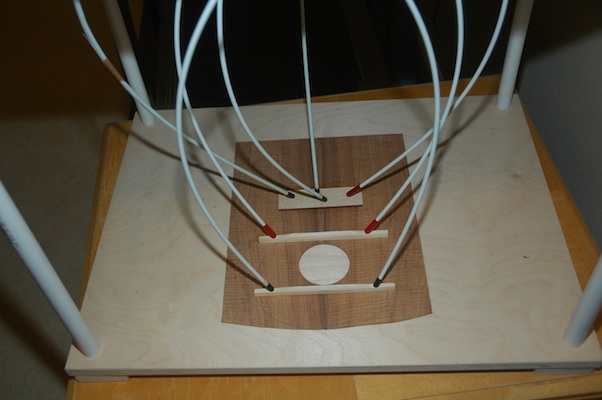

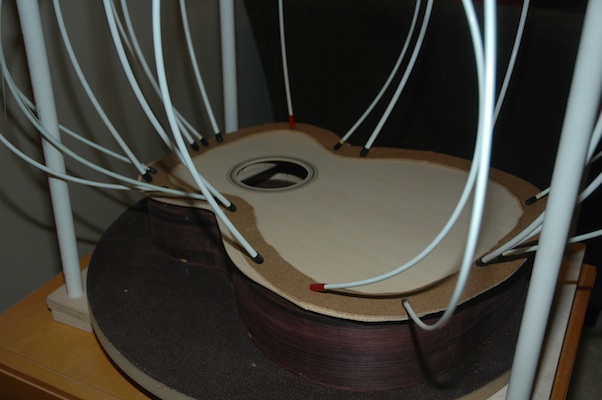

First, completed sanding and prepping the back and sides to accept the top.

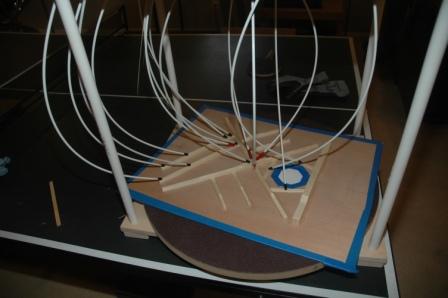

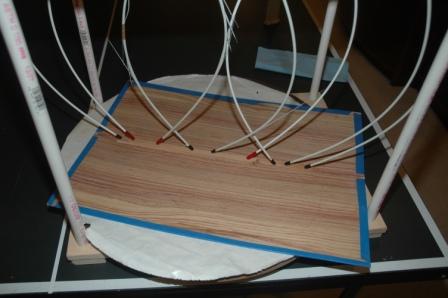

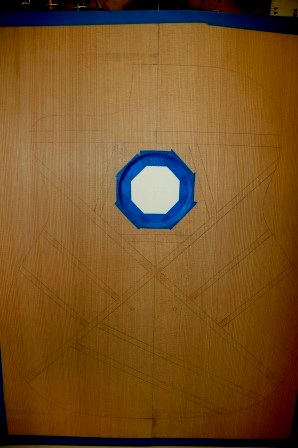

In the past I have wreaked havoc on spruce tops while bracing. I learned since to mask the top while I’m bracing to avoid dings and dimples.

Hey, it was from a calendar my WIFE gave me. The top is all braced and trimmed back ready for installation.

A couple of hours to dry, then I can cut off the scarf and start thinking about the binding and purfling.