May 13, 2010

I’m doing this repair for a colleague who bought it on eBay. Seller claimed it was “only a finish crack”. Right. The guitar obviously fell face first and the neck blunt forced the body into two cracks from the neck joint down through the body about two inches. I’ll need to remove the neck, clean up the cracked finish, then glue and clamp the cracks.

So first, remove the neck. Simple, 4 screws released, then neck pops out.

Neck has a tech’s signature and date of 3.20.03.

The cracks start at each side of the neck well and go down the back about two inches.

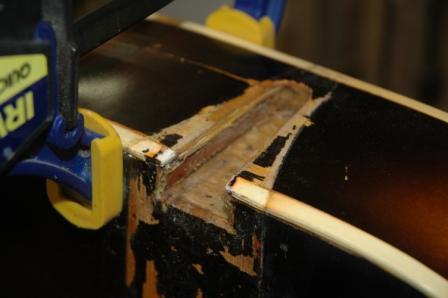

I applied CA glue to the back cracks, turned over then flooded the neck well with CA glue in the corners, then clamped.

While this was drying, I removed the bridge pickup to fix a loose adjusting screw. The screw which adjusts the height of the pickup became unseated, so it just needed to be reattached.

Kristina is either the tech who installed the pickup, or the previous owner’s girlfriend wanted to mark his guitar.

Next, fill the cracked lacquer, sand, polish, then bolt the neck back on.