April 21, 2011

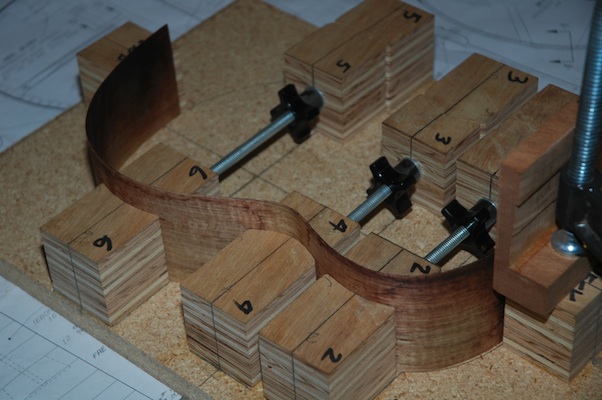

The first bent side is out of the bending machine.

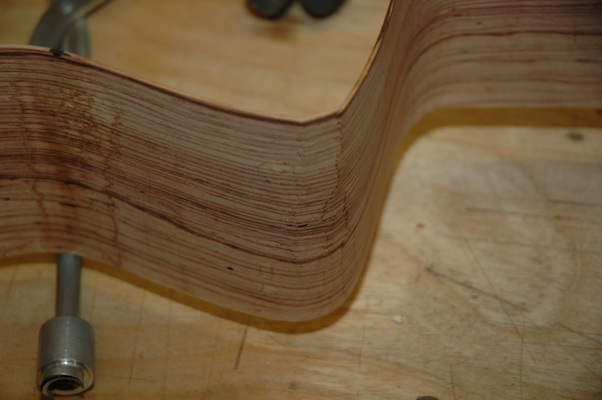

The resulting bend is accurate yet not tight enough. I’m resigned to the fact that I also need to apply more bend with the bending iron.

I’ve had limited success with the bending iron, mostly due to wood being too thick and preloaded with tiny cracks. The machine bend of the first side did produce two minor cracks, which I filled with CA glue. I took a first pass attempt at increasing the tightness of the bends with the bending iron, and found I could make some headway on tightening the bends and not introducing new or wider cracks: all due to the nice .070″ thickness of the sides.

I will complete the hand bending just prior to installing the sides onto the work board, which is still under construction.

The workboard will be finished with sliding cauls along the outside border of the sides. The sliding feature will allow me to use this workboard for dreadnoughts, OM’s and this Macaferri style body, along with others in between.

I usually build in a mold, which is only appropriate for guitars with dovetail or mortise/tenon bolt on necks. The workboard is necessary for the spanish heel type construction. This will all become obvious when I get to the step where the sides are glued to the top which has been attached to the neck.

I will have to provide a small radius bowl in the lower bout area of the workboard to accommodate radiussed X bracing.