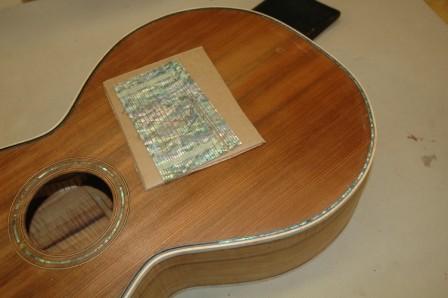

Guitar 906 – Paua purfling installed

October 30, 2009

Installed top curly maple binding with teflon strip between 2 BWB purfling strips. The teflon was removed after gluing to leave a channel to push in the Paua abalone strips.

Used mostly straight strips, which cracked (normal) when going around mild curves. When I got to the waist and the topmost section of the upper bout, I used curved strips. I used my thumbnail and a credit card to press the strips down into the channel.

The channel was prepped with a coat of vinyl sealer to keep the CA glue used in the final step from seeping into the side wood. Using a pipette, I flooded the channel with the paua with CA glue (one of many applications).

When the first flood dries, I’ll apply additional CA glue until the paua is full covered. Once covered, I can proceed with scraping the binding/purfling down to flush.