Archive for February, 2009

Guitar 902 – Top Bracing complete

February 26, 2009

Completed the installation of top bracing (after flooding and triming down rosette).

I still need to feather the ends of the braces down and perhaps scallop as well.

I’m ready to build a bending mold for the parlor body shape, then proceed with side bending and binding/purfling bending as well.

Guitar 902 – Koa back and sides

February 19, 2009

The Koa back and sides arrived today from Notable Woods. Very nice stuff. The sides are already down to .088″, ready for bending. Bruce Creps, the proprieter at Notable Woods shipped immediately after my order and was kind enough to drop in a headplate piece as a bonus.

The sides are narrow, but just right for my parlor width. I may have to reduce the depth of the guitar, but just a skosh.

The back will need to be thickness sanded before joining. I’m still waffling on the appropriateness of a back strip. This wood probably doesn’t need a backstrip, and depending on how well I can match up the plates, it may go naked.

Guitar 902 – Rosette and binding prep

February 18, 2009

Did a bit of work on the rosette. This guy will have a mahogany top, quite a different look than my other spruce top guitars.

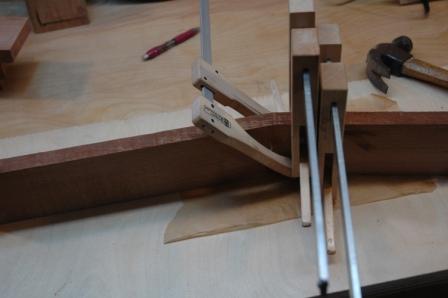

I’m prepping the curly maple binding by gluing a BWB strip before putting in the bender. This jig was constructed over a weekend with materials found in the street.

Guitar 902 – A new guitar is hatched

February 17, 2009

I have concluded that my next guitar will be a parlor for myself. This guitar will incorporate all the lessons learned from the last 6 guitars and will be a jewel. Slimmer neck, thinner back, sides and top, leaner bracing, all toward a better sound and playability.

It will be a mahogany top, koa back and sides, and very fancy purfling and curly maple binding. I will not proceed until each step is executed to perfection. I will NOT use any dolphin inlays or ergo shaping or new age soundhole placement. This will be a “pre war” parlor which references tradition and will hopefully sound like an angel sighing in the wind…or not.

I have most of the components already assembled. I ordered a koa back and sides from a local supplier, Notable Woods, and the rest of the necessities from LMI (see links). I had a mahogany top which was not used for my last parlor, which I will use now.

I have a large stock of mahogony neck blanks which I have assembled to craft the neck.

This started as a large hunk ‘o mahogany, and I milled down to 3/4″ slats and attached the headstock at a 13 degree angle and built a laminate stack for the heel.

All this is a reward step for completing my last guitar and keeping the momentum going. No rest for the bleary.