October 22, 2017

I have officially resumed building. I retired in June from teaching and have ministering to the health care and benefits schlmazel that was necessary to make the transition from employment. Now that I am enrolled in Medicare and supplemental insurance, I can get care for any workshop mishaps with sharp tools (both power and hand).

I have a parlor, an OM, a ukelele, and a Macaferri style guitar in the final stages of production. I’m also mentoring my son, William, on the construction of a Stew-Mac faux Stratocaster.

The parlor (aka 1201) and the OM (aka 1202) have experienced recent neck shaping and fretboard binding. Most of my recent efforts have been relocating the materials, tools and jigs I use. Mostly an effort in remembering where everything lives (which bin, which cupboard, which whatever?). Example: Last week I remember stumbling on a headstock template which I could use for 1202, yet, where is it? I put things down, make a mental note, then have great difficulty finding my mental note in my mental cabinet and subsequently spend time swearing at myself.

The upcomming challenge is to reset the neck for 1202 to remove the 14th fret bulge. This will require careful chisel work. I must confess my chisel work is still rudimentary; not at the skill level to which I aspire.

William and his Stew-Mac Stratocaster

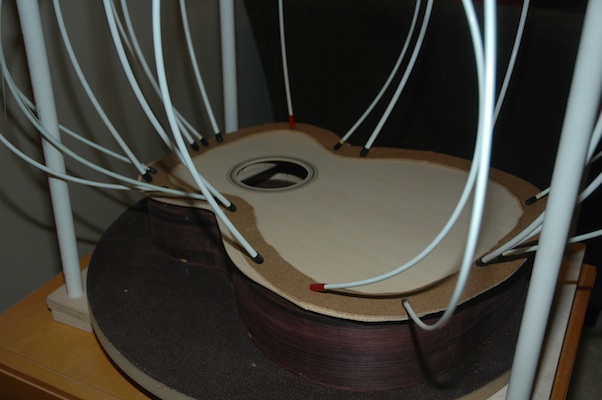

1202: Rosewood OM with Vine fretboard inlay

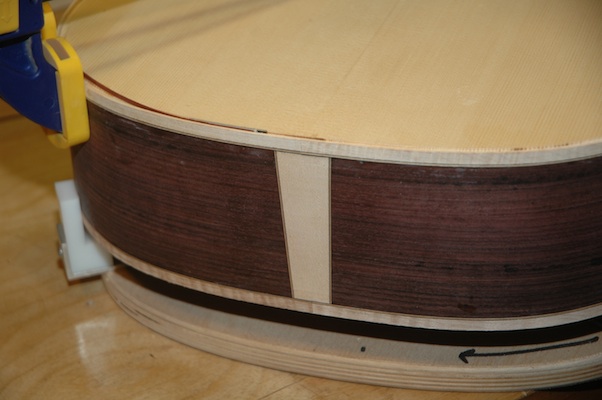

Rosewood binding on fretboard for 1201

Ivroid binding for fretboard of 1202.