March 19, 2011

Rachel returned from China/India Tuesday and she brought me a present.

She’s not sure what it’s called, so what’s it called? I need to restring, and I’m not sure what the bridge orientation should be.

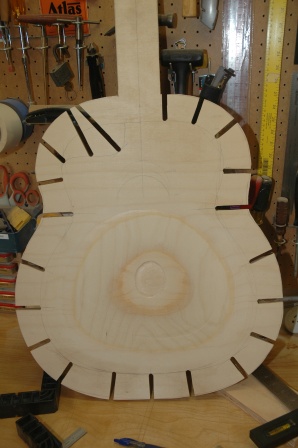

Today I added more lacquer coats to the koa dreadnought (6 of 12) and the uke (9 of 12). The uke is a disaster. It became dislodged from the spray booth bracket and fell to the cement causing a reasonable amount of damage, including pebbles throughout the wet lacquer coat, a chip out of the headstock, and a segment of binding with road rash. Oh well, file it down, keep going. Thank god this is just a “test uke”. I’m sure it will sound lovely, but it will look like shit.

I’m also refinishing a headstock on an eBay purchased Fender koa uke.

I have some aerosol nitrocellulose that I am using to refinish this headstock. It’s got 4 coats now, and I’ll probably go as far as 10.

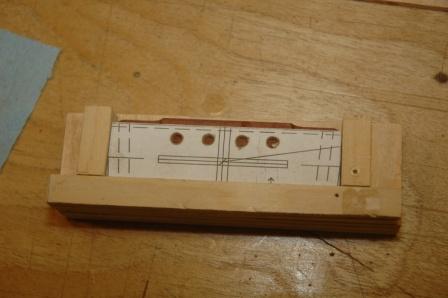

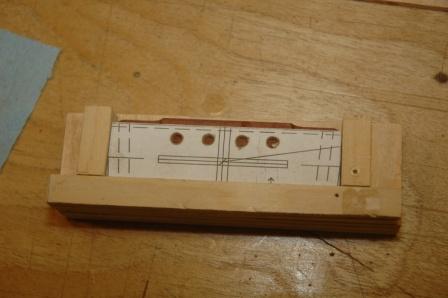

I devised a little jig for drilling holes in my uke bridges. I’m going to use bridge pins with strings secured inside the body with bone beads. I’ll get a picture up later of the string beads.