Archive for the 'Guitar 801 – 000 Mahogany' Category

Guitar 802 – Prepping for buffing

August 2, 2008

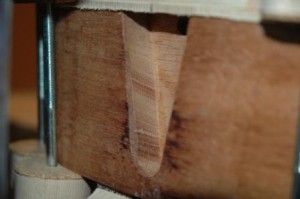

Finished the jig/vise which I will use to hold a guitar body upright. I built this in anticipation of having to sand the rim to smooth down flat before buffing.

I added a radius to the boards to compensate for the arch in the top and back.

The braces under the bench were 3/4″ too close to the bench top, so had to add a filler piece between the bench and the vise boards.

Finished it up by gluing carpet pieces to the inside for protection of guitar surface when clamping into vise.

It’s a nice day out today, so rather than use my newly crafted vise, I sat outside and held the guitar in my lap while I ran 600 grit sandpaper over the guitar, getting down to the brush stroke channels, and removing drips and dribble streaks. Next, 800 grit, then 1000/1200 wet sanding before I try out the buffer. I’ll definitely use the new vise for the buffing operation.

Headstock Inlay – Beautiful

June 2, 2008

Finally….Gurian Instruments, after two months, has delivered my custom made inlay and headstock veneer. There was a rush charge on the invoice?????? They took it off. The work is beautiful and I’m ready to rush to the workshop, chisel off the ebony headplate on guitar number 2 and glue on my new stuff!

Guitar 0108 – Should I sell it?

May 31, 2008

It’s getting to the point where I can actually think of selling the guitars I am making. Yes, I’m very attached to my first guitar, and I love how it sounds and plays, but maybe, depending on how well number 2 sounds and plays, I’m ready to let it go. Anyone out there interested in a conversation about buying one of my guitars?

Guitar 0108 – March to completion

March 7, 2008

Cheated it by a day. Started sanding and polishing. The polishing used a foam disk on my power drill and it was a chore to keep everything stable while I tried to polish. I’m not sure the lacquer finish will be my choice for future guitars, but if it is, I need to look into a buffing wheel, perhaps mounted on my bench grinder.

After buffing, glued on the neck. It wasn’t as good a fit as I desired, as the dovetail is a difficult prospect. My next guitar has a bolt on, and I’ll compare the quality and ease of working.

Followed with the bridge. Found I didn’t have clamps to reach the 5″ reach from the sound hole to the bridge ends so foolishly clamped directly to the top and back. It was a technique of desperation and it worked out well, but could have been a disaster to the box. I will need to acquire the proper clamps for the next guitar.

Guitar 0108 – January February log

January 26, 2008

Released the neck/fretboard from the rubber band clamp, cleaned up the dried glue squeeze out.

Made a significant order from StewMac for finishing supplies and a bench vise. Arrival due next weekend. In the interim, I carved out the neck around the headstock diamond, filed down the fret ends, trimmed up the fretboard to be flush with the neck stock, and sanded the neck. Still need to clean up the neck foot which I glued the end cap to. Prior to receiving the finishing supplies, vise, and special fret beveling file, I can begin the process of shaving and shimming the neck dovetails. Should be interesting, as this seems to be the most technical and accuracy will be at a premium.

Guitar 0108 – Log Entry – December 2007

December 25, 2007

Received kit (#5297): OOO Mahogany Dovetail neck joint. $395.00. Review of printed instructions and instructional DVD made it evident that acquiring tools was going to cost more than the kit.

December 26, 2007 – January 19, 2008

Reviewed printed and DVD instructions several times before embarking. First steps included determining which side of the prebent mahogany sides was the top vs. the backside. Apparently, I had a 50 50 chance of getting it right, and failed. I glued the neck block and the end block and only after did I discover my error. Using some bit of intuition, I realized I could keep the tail block in place, augment one end with a glued veneer of mahogany from the scrap that came with the guitar in order to have enough height to account for the 5? back angle. But, I did have to remove the neck block to rotate 180? to expose the open dovetail to the top. Using a flat iron, butted up against the neck block, not touching, on wool, from the outside of the guitar, I heated up the glue. Rachel was kind enough to run out to Fred Meyer for an art supply spatula, which I used to separate the neck block from the sides. Rotated and reglued, but again erred in not getting the neck block perfectly square with the sides. I will have an interesting challenge in setting the neck if this out of square is too pronounced.