Guitar 1202 – Binding and Purfling

January 27, 2013

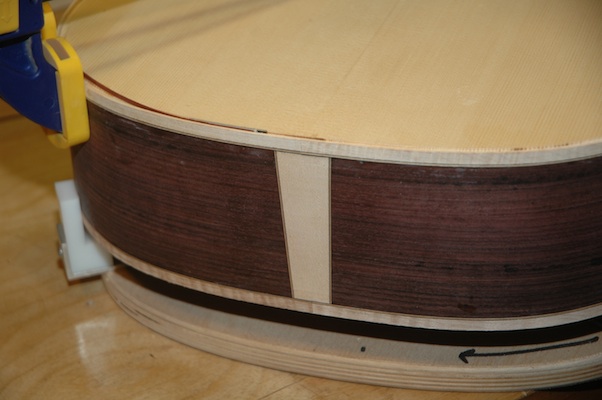

I have finished installing the binding. I’ve taken an alternative approach to this guitar. When purfling the top with Abalam, I have, previously, installed the binding, purfling, teflon, purfling sandwich all at once. It has been a tricky juggling process which guaranteed binding cracks, gaps, unseated purfling strips, all because I had to weave 4 different layers into the channels which were slathered with glue, then with my third hand (which I don’t have) apply the binding tape to hold it all in place.

This time, I installed the binding solo, and will clean out the glue overage, then drop the purfling, teflon, purfling sandwich into the open channel.

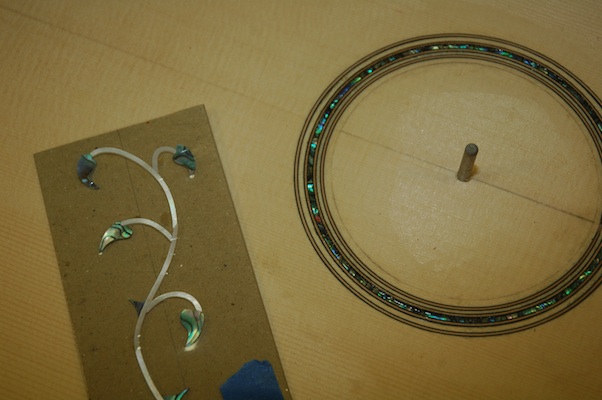

The photo shows the purfling strips with teflon between, and abalam in the channel after the teflon is removed. Currently, the binding glue is drying, and a variety of cracks are being repaired under clamps.