Update: Uke Parlor Hybrid

August 26, 2012

Yeah, Guitar Camp was awesome, and now I’m home counting the days before I start back teaching. I took a uke and an OM to camp, and as usual garnered a lot of interest from fellow campers who claim they “must have one”. On the last day of camp advice is given to those of us returning to the non-camp world. One bit of proper advice was, “Wait three weeks before accepting a proposal of marriage from a fellow camper.” Same goes for committing to a new uke or guitar.

I’ve resumed where I left off before camp. The Hybrid for Jim has a first coat of pore filler (an epoxy resin) and is lined up for the spray booth.

I’ve installed all binding on the Myrtle Parlor.

I then did what all good builders should do, I burnished my cabinet scraper. Ah, what a difference! Several smooth strokes across the top, and the binding is trimmed flush with the top.

I’m so in love with my first uke. I played it at camp and caught the bug. The uke I’m working on now is really for me (so I’m differently motivated). The top is braced, the tonebars are installed and the neck and top have been joined.

The neck has been stabilized with a graphite rod which lives under the mahogany strip in the center of the neck.

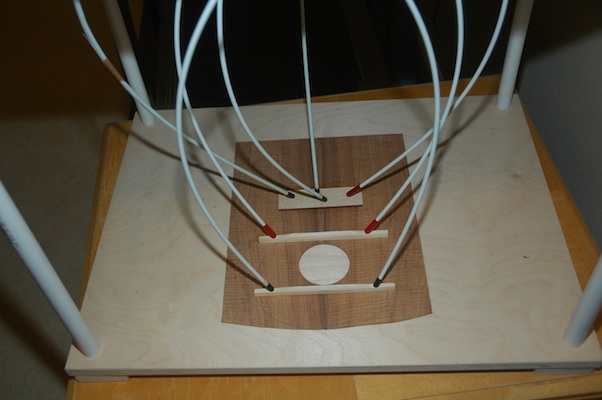

First the bracing and bridge plate were installed.

Then the tone bars.

Finally, the neck and top can be joined.