Happy New Year to All

December 30, 2012

This will be my last post of 2012. Some things were accomplished in 2012, but all in all, the pace of this year’s building has ebbed in relation to previous years. I could chalk that up to a new career teaching mathematics, but really it’s a case of shifting priorities. I have endured a few crisis moments all around finishing with spray lacquer. As reluctant as I was to put down the spray gun, it is for the better. I cannot continue to subject my families health and my health to the lacquer fumes inherent with nitrocellulose lacquer application. My options are twofold: send guitars out for spray services ($500) or procure hard to find water based lacquer and spray with this less toxic alternative. I’m still on the hunt for water based with mixed results.

I have been working diligently on my uke, Rachel’s parlor and Susan’s OM. What follows is an except from recent work.

Rachel’s parlor has taken a step forward with neck shaping and fret dot design.

The fretboards for Rachel’s parlor and Susan’s OM are seen below the beautiful Myrtle back.

The parlor neck is on top with the Cocobollo headplate. The OM neck is shown with the rosewood headplate.

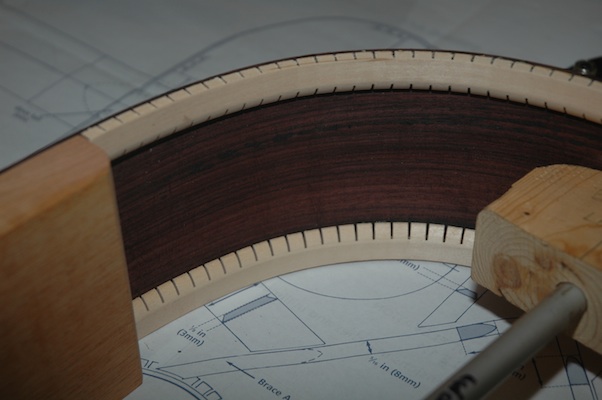

I’ve managed to shape bracing and install the back to the sides as well as lay down the top bracing for the OM.

The second picture shows the back after the scarf has been trimmed.