Archive for the 'Guitar 803 – OM Maple' Category

Guitar 803 – I made it! Before year end!

December 30, 2008

Wow. I promised Larry way back in October that I would have his guitar ready for him. I failed, did not fulfill my obligation, and felt a bit awkward, but he and I agreed that things take their time, and his guitar would be ready at the appropriate time. And now is the appropriate time. I finished (relative term) his guitar and delivered to him this very evening. It still needs the LR Baggs electronics installed, but I want him to take it home and give it the old go around and come back to me next week for tweaking and fine tuning and.. the install of the LR Baggs.

Many steps to getting the guitar ready for Larry. Strings on is one. Spent several iterations getting the strings settled properly. Did have to shim up the saddle twice, but well worth it.

Just damn proud of the SMG label inside the soundbox.

The sycamore headstock turned out very nicely and without my compete knowledge, I bought (gold) strings which were complementary to the whole gold tuner/fret thing.

So, here’s the baby, bridged, stringed, cradled, and ready for Larry to accept.

So, the first thing is, you must nestle the thing in the new case. Just to make sure it fits and it has a home. And…yes, it fits. More importantly, does the player/owner love it? Oh yes.

This almost looks like a Shamwow commercial.

Now here he is riffing some Pink Floyd, or is it Moby Grape?

And finally, he looks so happy, the next thing he did was walk out the door. I suppose he really likes the guitar. He’ll tell me next week.

I spoke with Carl tonight, and with the combination of giving up one of my babies (guitar) and speaking with my music partner who has moved on to another city, I got a bit schmelke (sad, melancholy).

It’s hard to see your craftwork depart and your music partner so far away.

The good part is they both will come back to you someday.

Guitar 803 – Buffed and installed neck

December 29, 2008

Hey, it’s Rachel’s birthday! Happy Birthday Rachel. She is no longer a teenager, and she made it to twenty!

Completed the sanding of the lacquered neck and body through the 1200 wet sand then used my buffing wheel for the first time. First, several passes with the fine compound and the muslin wheel, then finished off with the dormet and the very fine compound. Oooh, looks great!

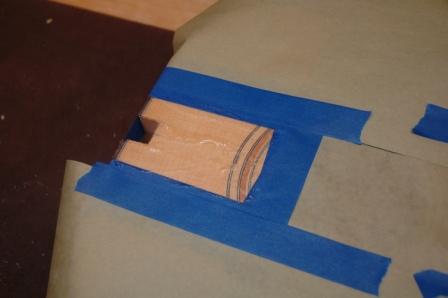

Since I chose to finish the neck and body separately, I needed to strip off the lacquer where the neck glues to the body.

First, mask off the area in preparation for the Stripeze. Then apply the stripper, scrape off, apply again, then scrape off again.

Do a little sanding, practice dry fitting and clamping before applying glue (to the fretboard extension only, as I am using a bolt on neck). Glue up the fretboard extension, bolt in lightly, apply clamps, tighten bolts, tighten clamps, tighten bolts, and….neck is installed. It will now sit for a couple of hours before I take similar steps to install the bridge.

Guitar 803 – My email to Larry

December 16, 2008

Larry,

I spent several hours tonight with your guitar. I know every nook and cranny (how trite is that!). I have wired my workshop for sound, and as I sat diligently sanding with 600 grit, bringing everything down to baby butt smooth, I had Django Rheinhart on the CD player and it was about as good as it gets. Good because the music was excellent and the results were equal. Your neck (not your neck) and your body (not your body) have become the smoothest most glorious objects which leave me wanting only to stroke and stroke. There’s nothing more lovely.

I examined and became familiar with every curve and surface as I sanded, and I know your guitar like no one ever will. There are gaps and blemishes and ripples which are so small and indiscernible that only I will know them. I say this only because, if you or I were to examine our own present guitars, these things would be there, but we wouldn’t see them. Only the one who spent hours sanding and checking and cleaning and sanding, would recognize these small communities.

It’s really a nice collection of excellent wood. It’s not a guitar yet, but it’s going to be a great guitar. I’ve been doing the tap tap tap thing trying to imagine the sound it will make when finally the strings are on. It’s soon. I know your patience has been tried, and as new age as this may sound, and as many apologies as I can make in advance for saying it, this guitar has determined its’ own pace as to when it decided to be completed. It currently has given me the directive to get my shit together and wrap it up. It’s hours away from being played.

Guitar 803 – Over the hump

December 14, 2008

Much dismay over the amount of sanding I need to do to get the KTM-9 lacquered OM Maple ready for buffing. I sanded with 800 grit until I brought on a premature bout of arthritis. No progress seemed to be made. I wasn’t getting down through the “orange peel” no matter how much I sanded. I went back to 600 grit and the difference was remarkable. So I went over the neck and body with 600 and got amazingly close to removing all the orange peel and was quite encouraged once again to go on.

Here’s Hulk after the 600 grit go around waiting for further sanding. Behind is zebrez, the zebrawood resonator guitar body.

I need to build 2 or 3 16 degree sanding blocks to tackle the fretboard. As it is maple and needed a lacquer finish, I sprayed with the frets in, and need to get between the frets with the sanding blocks to smooth up.

(You might notice that the pictures are a bit larger, I’ve compressed less, and like this resolution better.)

The headstock is sycamore, which I’ve learned is closely related to maple.

I spent some time this weekend collecting the parts I needed to complete my buffing station. No one seems to carry motor pulleys, but found what I was looking for at Stone Hardware. Only remaining “thing” for the buffing station is a clamp or spring to pull the motor away from the arbor to tighten the v-belt.

Guitar 803 – The finish will cure

November 24, 2008

Staying home from work this week. We’ll drive to SLC for Thxgvng Wednesday morning. I planned to work on guitars up until we leave for SLC. Today I put the final 4 coats of lacquer on Larry’s Green Guitar. I think I’ve got the hang of it now. The whole spray coat process takes about 5 minutes, with a bit of prep and cleaning during each spray. With an hour between coats, it’s about 3 hours of time blocked out, with opportunity to tackle something else while the coats dry.

Guitar 803 – My patience is tried

November 15, 2008

I ran out of KTM-9, the water based lacquer I am using to finish the guitar. As I awaited a restock, I was frustrated by not understanding the control and use of the new spray gun. It seemed all my sprays were mostly air, and I was not getting lacquer to the guitar. Much cleaning, reading, pondering, let me to believe my gun was clogged due to not cleaning between coats.

I found some literature suggesting the use of denatured alcohol as a solvent for KTM-9 and cleaning the gun between each daily coat, and not waiting until the days final. The restock arrived and I blithely moved to the spray booth and proceeded to put way too much on the first coat, creating runs, runs, runs, which I now have to sand out before going too next batch of coats. God I hate removing lacquer runs. It’s worse than going to the dentist. I do not want to go down to the shop and fix my mess. Instead of progressing, I am falling back. Maybe there’s a guy on craigslist who sands lacquer, I could stimulate the economy by providing jobs.

Regardless of the runs in the finish, the lacquer is now flowing on to the guitar, and I’m starting to see some real shimmer and depth in the green maple.