Guitar 1002 – Redo Binding

April 29, 2012

I just wasn’t happy. The binding on the front of the guitar, the binding everyone will see and admire, was just not right. Too thin in places, poorly fitted around the cutaway, and even a few cracks that needed repair. I ordered additional rosewood binding strips, which arrived yesterday, and set out on removing the first application of binding and installing it again.

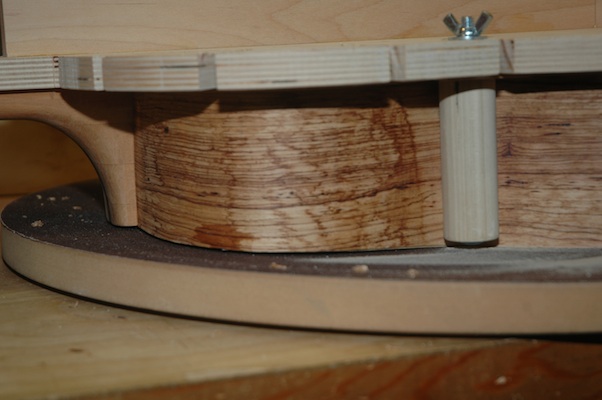

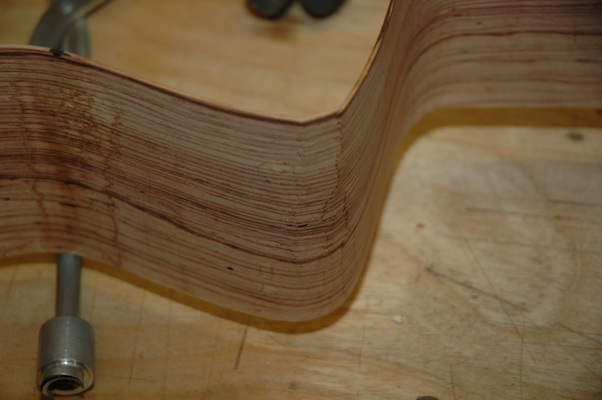

I routed out a binding channel for the top binding with a depth considerably deeper than the original. The first pass at installing this binding included thinning of the binding strips to assure a clean bend around the cutaway. What I discovered was that I could tightly bend even full width binding if I got my iron hot enough and patiently bent the binding strip a wee bit at a time. Bending, then checking, bending then checking, until I had a nice tight bend with no cracks or pullaway of wood fiber on the outside of the bend. (What I did find is that my insulated gloves don’t work as well as I would like, and my fingers are a bit crispy).

A good tight bent binding and purfling make for a spectacularly easy application of the binding with binding tape.

This will be way better. I am no longer afraid of the tight bend of the cutaway.