October 18, 2008

Just 18 more days until Barack Obama is elected. Wish it was tomorrow.

I pretty much completed my workshop remodel on Friday. There’s still a lot of cleanup and organization to do, and maybe Carol will help me with that tomorrow.

When I have multiple projects going on at the same time (like the Koa Parlor, the OM Maple, and the banjo rejuvenation) I work on the one that is the most fun. And, I really like putting on the binding and purfling. So even though Tom is wondering when his banjo will be done, and Larry is patiently waiting for his maple OM (which I will call the Hulk), I gravitate to the Koa Parlor as it is in the phase I enjoy the most.

Spent a lot of time ensuring I had the right depth and height for routing the channels, and tackled the back first.

Preparing for the gluing is key. Get all those binding tape strips ready, square off the ends of the binding, slather on the glue, and get going. I’m always a bit sore in the forearms after applying the binding tape as the tight fit between binding and body is essential, so I really bear down on the tape as I’m putting in place.

It doesn’t need to be taped long, maybe a couple of hours, but I left for at least 4 hours before removing tape.

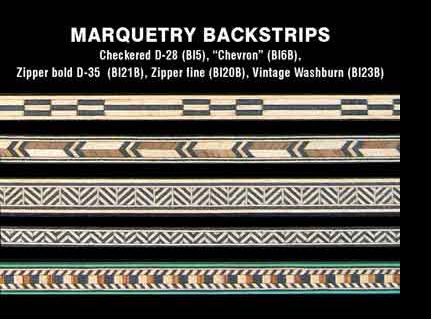

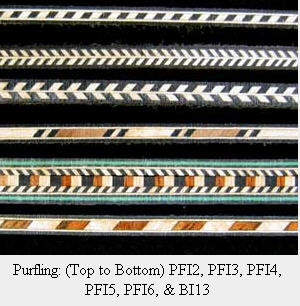

The top is a bit more complicated as it is binding and purfling. The purfling is the decorative strip between the binding and the top. It requires two channels carefully routed.

This side is quite a bit messier than the back, making sure to get all the glue in all the faces that need it: in the channels, between the binding and the purfling. I prefer too much glue to ensure that glue gets everywhere it’s supposed to. I don’t want any gaps, and missing glue spots can allow gaps to open up. Again, taping is more difficult than the back, and keeping up with the drying glue and getting everything pressed firmly together and against the top while pulling down the tape is a bit tricky.

Tomorrow, I can remove the tape and start scraping. But….maybe I’ll work on the banjo and the maple OM to keep my boys happy.