November 2, 2008

Well, after much procrastination, I have finished Tom’s banjo refret. It was much more than a refret, and I had to do a bit of adapting to get it strung and playable.

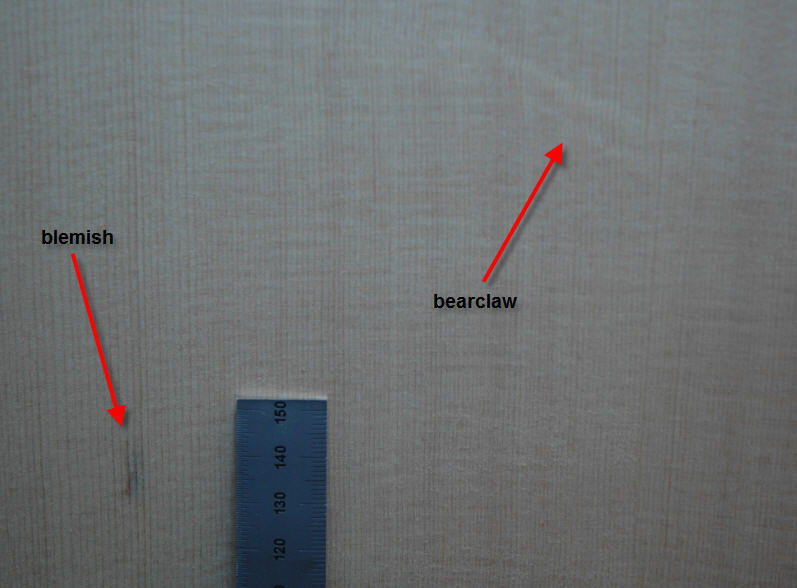

1. Sanded down old fretboard veneer, installed a new rosewood veneer top, slotted for frets, banged ’em in, and added abalone dots and star fret markers. Before banging in frets, I sealed the rosewood with Z-poxy pore filler, then buffed back to get off the sheen and finished with lemon oil.

2. Added replacement head clamps where missing. These were a bit too long and had to grind down ends so as not to have pokey bolts gashing open the abdomen of the player. The remaining original head clamps were tightened as each was loose and dangling.

3. Drilled out headstock to accept new tuners. Ground and sanded back the rear side of the headstock to make it parallel to the top, applied tobacco brown stain and 9 coats of nitrocellulose lacquer. Did NOT buff out to a glossy sheen as it would compete inappropriately with the rest of the neck finish. Installed new tuning machines.

4. Added string button to 5th string near 5th fret. This is like a mini-nut. The banjo neck was a bit rotten and drilling for the button was precarious and some of the rosewood veneer flaked off in that location. I’ll leave it as is given there is no good alternative except to try and glue in some rosewood veneer flakes. I’ll get Tom to make the call as to whether he wants that done.

5. Trimmed and polished bone nut material and installed with super glue. Slotted to accept strings. Filled hole in end of neck where it screws to the head (toothpicks and AR glue). Drilled out a hole dead center then mounted neck to head. Installed string tailpiece.

6. Even with the shortest bridge, the action was unacceptable. The neck mount with the existing holes left the neck with no oblique angle, so strings rose dramatically from nut to bridge. Removed end bolt and drilled new hole in tone ring to create a better neck angle for better action/string clearance. I also inserted a rosewood shim between the end of the neck and the metal rim of the head to accent the angle further. Even with all this (and it’s the best neck angle possible with this configuration), the action is a wee bit high. Lastly I deepened the slots in the nut to get the strings even closer to the frets.

With the bridge positioned properly, it plays nicely and even sounds in tune (an achievement). There’s some detail work to be done, but I’m hoping it’s something Tom wants to tackle.