Archive for the 'Guitar Building Logs' Category

Guitar 906 – Oooh it gets sparklier every day

January 10, 2010

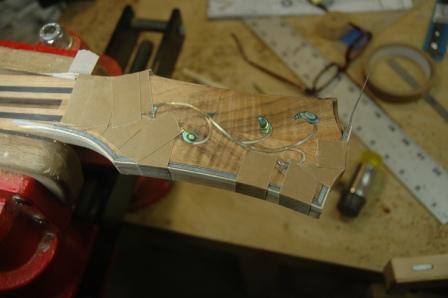

Not a word, sparklier. I meant more disco ballish. No, just more better. Lots of time, but result is worth it. Installed the maple/bwb/teflon/bwb into the headstock segment by segment.

After the process was complete and the components dried, the teflon was removed and paua strips were pressed into place then flooded with CA glue.

Played poker later in the day and drew a pair of aces….ha.

Guitar 905 – Body bound, head bind, head press

January 10, 2010

Finished the binding of the body, lots of cleanup and sanding to do. I love/hate this part. It’s a lot of work, but the result is oh-so-satisfying.

Tackled the headstock binding: first routing out the channels to accept the very simple maple, bwb.

Installation of the binding and purfling was quite straightforward as this headstock is all square, little curve.

End result, just fine.

Guitar 906 – Binding the Headstock

January 9, 2010

This guitar, which has been dubbed “highly decorated”, will get a paua purfling with curly maple binding. First step was to channel out the area where the binding and purfling will be inserted.

The construction is done in steps, unlike the binding of the body. I will install/glue in the curly maple, bwb, teflon, bwb in phases, each sandwich installed in one segment, allowed to dry, then followed by the next segment. This will necessarily be a slow process while waiting for the glue to dry for each segment. Looks like some multitasking is in my future.

I did get a few new repair jobs over the holidays, and I plan a fret dressing for Beth’s OM, so there’s no lack of opportunity.

Guitar 905 – Binding (Curly Maple) Installed

January 9, 2010

I haven’t been posting over the holidays, but I was still working. Spent lots of time installing the curly maple binding with the BWB purfling. Got a hint/trick from Rick Davis. After the binding is installed, often there are small gaps between the binding/purfling/guitar body. In the past I have filled these small gaps. Now, after the glue has cured, I clamp the binding where there are gaps then use a heat gun (think hair dryer with temperature control) and apply forced air heat at the gap, and magically, the glue softens and the clamped area gaps tighten up. Very cool.

Next step is to level/sand the binding to be flush with the guitar body and prepare for the neck fitting.

Wintergrass 2010

December 24, 2009

Wintergrass is a family-friendly Bluegrass music festival, with concerts and dances at 4 different stages. There are also two Academies, workshops, impromptu jams, and a chance to see and hear some great music. This year it is being held in Bellevue, WA, Februrary 24 – 28.

I will be displaying guitars 905 and 906 as part of the Seattle Luthier’s Guild exhibition. If you are attending, drop by the exhibition hall and take a look.

Guitar 905 – Rebraced, box assembled, ready for binding

December 20, 2009

I reinstalled two new lower bout braces to bring the back to a 15′ radius dome. The first step was to remove the original braces then put the back on the 15′ radius dish held down by the go-bar clamps. Once the new braces were shaped and kerf was removed where the braces meet the sides, they were glued in place and clamped in the go-bar platform. Kerf was then reinstalled over the braces.

After drying, the top was glued on. The back and sides were no longer in the mold, so to ensure the back dome remained, I clamped the back down through the soundhole, then glued the top to the sides. After setting, I removed from the go-bar and trimmed the top and back scarf using a flush router bit, sanded the hell out of the whole thing then installed the butt graft.

I sawed fret slots through the installed inlay and sanded the headstock in preparation for binding the headstock.

To protect the top during the remainder of construction I applied a light coat of shellac. It will be sanded off prior to finishing with lacquer. Here’s a first look prior to binding and installing the neck.

Guitar 905 – Teapot dome

December 19, 2009

Discovered that the backplate dome had compressed. This means that the natural dome shape of the back had flattened. This is not a good thing. Many options, but the best was to remove the lower bout braces and replace, then assure the dome is retained as the top is installed.

So the first step was to use the dremel to scour out the bottom two ladder braces and keep it in the go-bar clamp to teach it to be radiussed in preparation for installation of new braces, a little beefier and spruce instead of mahogany for lateral integrity.

Once the braces are installed, new kerf pieces were installed to hold the end pieces of the braces down and retain the dome. I’ll hold the back braced box in place in the go-bar clamp until I’m ready to install the top.

The top is fully braced and has the appropriate tap tone and is therefore ready for installation. I’ll let the back and braces sit overnight to cure before I install the top.

I’ve used a scallop approach to bracing the top. After repeated tapping, I think that this arrangement will produce the tone I’m looking for. The top is around .120 to .115″ thick, the bracing is sufficiently scalloped and feathered to zero toward the kerf line. As guitar building is controversial, some will say “don’t feather, you idiot” or “the soundboard is not a speaker cone, you idiot” or “did you hear the falling of the water over the pebbles of Buddha” or “what were you thinking?”. All of these comments are valid, but we must take our own journeys and arrive at our own conclusions. I think, based upon what I hear, that this guitar soundboard will sing. If not, many of us will be disappointed.

I signed the top plate, and tomorrow it gets installed. Whee.

Guitar 906 – Oooh it is looking good

December 3, 2009

The inlay is looking really fine. After the epoxy dried, I was able to start sanding down to see the eventual end product. Here’s the headstock.

The fretboard needed lots of sanding.

The result was quite nice.

Put together, you can imagine what the end result might look like.

Carl asked me about the issues with the fret slots after the insertion of the inlay. Yes, it is an issue, but I laid out the inlay so as to avoid as many fret crosses as possible, and to align the leaves at the appropriate frets. In the end I had to saw through the frets where they were crossed by shell. It worked out well, and I’m ready to install the frets.

Carl, are you there? I’m thinking of adding a little bit of additional inlay, but it may be a bit too self aggrandizing. Take a look at the following and let me know if you are ammenable to allowing me to self promote.

It might be too much to drill my initials into you fretboard, but I thought I’d ask.

Guitar 905 – Prepping for headstock and fretboard inlay

December 3, 2009

Used my newly acquired skills to outline the headstock handprint inlay then saw out then lay on the headstock for tracing. Did the same lay on the headstock with the peghead shell procured from Luthier Supply.

The customer wants a torch style inlay on the fretboard, which I also procured from Luthier Supply. I showed him two options, 5th fret or 12th fret, suggesting the 5th fret would be better as there will be fewer fret crossings which hide the inlay.