February 13, 2011

The stage is set for the dreaded retreat to the spray booth. Spraying lacquer is a process which is a whole lot of setup followed by very brief spraying sessions culminating in a necessary yet dreaded cleanup. It behooves one to have several guitars ready for spraying at the same time. I have delayed spraying the koa dreadnought to get the walnut OM and the bubinga tenor uke ready for spraying as well. That’s three instruments staged for spraying at the same time.

I have traditionally used nitrocellulose lacquer, with excellent results but questionable effect on my respiratory system. Even though I use a vented booth and a respirator mask, I have experienced deleterious effects from the nitrocellulose. This round of spraying will employ a water based lacquer, KTM-9. I have used KTM-9 in the past, and applied it with a brush, and the results were good, yet I anticipate the spray application to be excellent.

I have had mixed results with the pore filling steps, and this time am committed to ensuring the pore filling will be immaculate regardless of how many applications I need to fulfill a mirror surface on the back, sides and neck.

The proposed steps are:

1. One coat of lacquer sanding sealer

2. Several applications of pore filler, until smooth

3. Sand until smooth without penetrating sanding sealer

4. 3 coats of lacquer applied every hour

5. Cure 24 hours, scuff sand

6. 3 coats (that makes 6), cure 24 hours, scuff sand

7. 3 coats (that makes 9), cure 24 hours, scuff sand

8. Determine need for 3 more coats or proceed to finish

9. After 2 weeks of cure, progressive sanding, starting with 400 through 1200 wet sand

10. Buff

These steps precede attaching the bridge, bolting on the neck and moving to final setup (fret dressing, nut and saddle shaping, install tuning machines). Based on this schedule, I am about 3 weeks away from completion.

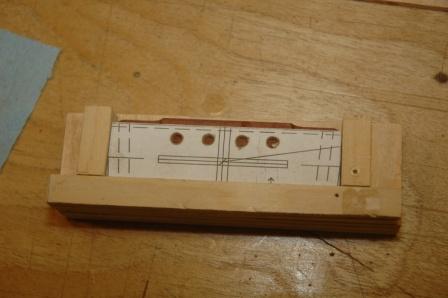

Spraying is a lot of hurrying to wait. I can fill the gaps in time by continuing on construction of the hybrid Macaferri and the koa tenor uke. Next week I will be receiving a cutaway ram to install on my side bending machine. I have also devised a use for this ram on a side bending machine built purposely for uke sides. Since my current machine is too large to properly bend uke sides, I am constructing a bending platform which will use the cutaway ram for the waist bend for uke sides. Pictures coming later.