Guitar 1002 – Kerf, Side Supports, Ready to Radius

February 5, 2012

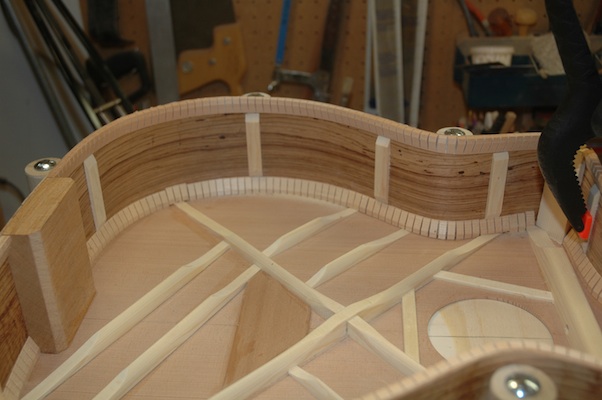

The sides have been trimmed down to the approximate height to simulate a 15′ radius. I used my wee little finger planer which served well. Before using the radius sanding dish, the kerf for the back was installed.

Additionally, side supports were glued in. These serve to keep the integrity of the sides and avoid cracks along the grain.

The box is ready to be radiussed. Using a 15′ radius dish mounted with sandpaper, the kerfed sides are dimensioned to a dome shape, tapering down from the butt end to the neck end. Once this is done, the back can be installed. I will use spool clamps with the box on the workboard to secure the back to the sides.