Guitar 805 – Warped back continues to plague

January 10, 2009

I made some advancement on working the rosette for the spruce top, but discovered I did not have enough BWB binding. I installed the inner and outer ring, and will complete the center ring which will be BWB PAUA BWB when I receive the BWB I ordered today.

I measured the thickness of the wood on my Taylor 12 string, and at 3.4mm, I confirmed I had the thickness of my top and back around 3.5mm and proceeded with the rosette and the back reinforcement strip.

Here’s what the back looked like before adding the reinforcement strip.

I used my gobar platform to install the strip, and also forced down the warped sides into the radius dish to allow the glue to dry with the back in it’s eventual shape.

I was concerned about the cracking sounds that accompanied the clamping. My concerns were confirmed when I released the back from the gobar and saw the backstrip had split.

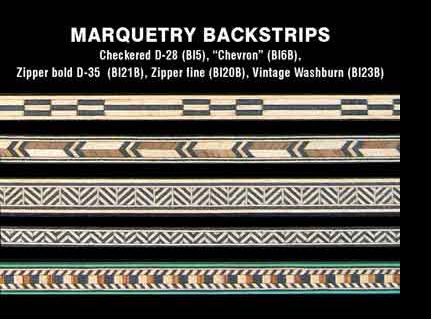

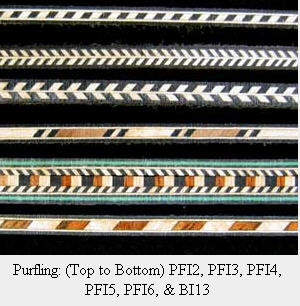

So, now I am double trouble. I don’t have another backstrip, I don’t have another back reinforcement strip, and the warped sides won’t like being braced without breaking the backstrip again (I suspect). So, as part of my emergency order for BWB for the rosette, I added multiple backstrips, multiple reinforcement strips, and to be on the triple safe side, multiple curly maple binding strips and purfling (these objects will be bent in my bending machine, and God knows, I will probably break a few in the process of bending).

The beauty of my task list, mentioned in the previous entry, is that I have several task paths which I can take should one or more tasks go south on me, like the one with the back.

I worked a bit on shaping the neck, bringing the thickness of the headstock down to 15mm, drilling holes for the tuning machines and installing fret dots.

I have decided to install the tuning machines “down” as I like the balance better.

Here they are “up” (the tuning peg exits the shaft on the upper side).

“Down”. I still have some right side peghead removal to get the dimensions balanced. It’s a little fat on the right.