Back in the shop

October 20, 2009

Yes, it’s been three weeks since I laid hands on any guitar work. The primary distraction has been the building of a new spray booth. I constructed an enclosed booth in the garage with an exhaust fan, lighting, electricity, and units to hang guitar components for spraying and drying. The majority of the work is done, it just needs a few wrap-ups from the punch list. I will complete those wrap-ups just prior to my next need for spraying guitars 905 and 906.

I have a considerable backlog of work. The following list is to help me prioritize.

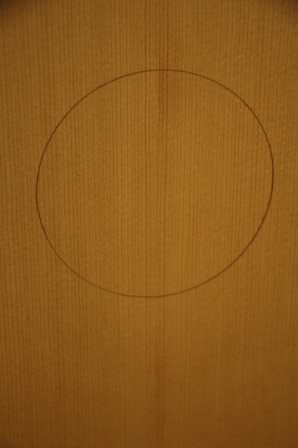

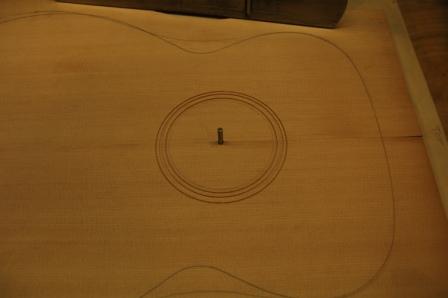

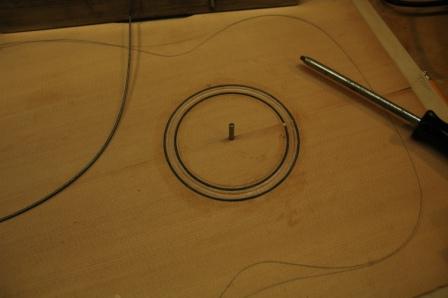

1. Guitar 905: Back is attached to sides, next step is to finish brace shaping and sanding for the top, then installing the top.

2. Guitar 906: Box is assembled, next step is to bend binding, route, then install binding.

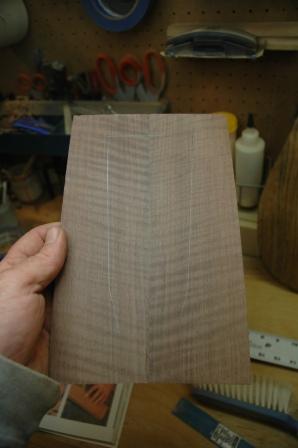

3. Guitar 903: This guitar still has no identity, yet I’m leaning toward a dreadnought, just because. After I adjust the drum sander, I can thickness sand the sides then bend. I need to identify and prepare a top. The Ovankol back is joined and ready for thickness sanding.

4. Oliver Classical Guitar Repair: Thank God my brother in law is understanding. Starting this repair is hard to think about.

5. Oliver A Mandolin Repair: I’ll begin tackling this repair ASAP. I know what needs to be done, it just needs to be done.

6. Tepp A Mandolin Repair: Much progress made, much to go. It will be a good companion to the Oliver A Mandolin repair.

7. Tepp Ukulele: Modest repair can be done now that I have my RARE Earth magnets.

8. New Repair Job: Expecting a guitar to come into the shop Wednesday to improve intonation, probably through a bridge saddle replacement.

Stand by, the Dude Abides.