Guitar 0208 – Finish implies finish

July 8, 2008

Getting this guitar finished (completed) is drawing out longer and longer. Because I used a brush on water based finish, I have a surface texture full of brush lines. I don’t think it’s because of my technique, but rather the inherent issues with brushing, regardless of the claims of the product to dry smooth. I may continue using the water based lacquer, but only if I spray. I also will finish the body and the neck separately, as doing so joined, I have created a zone of undesirability in the areas where the fretboard meets the top, and the neck meets the body.

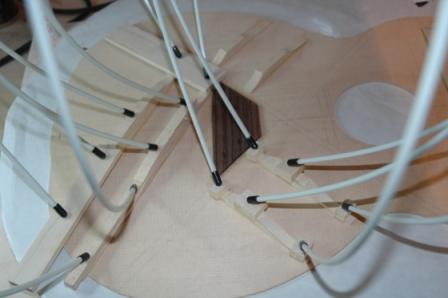

I built an adjustable workboard to hold the guitar to the workbench. This will allow me to work vigorously on the top, back, and neck as I continue to sand out the brush lines, then progressively work through finer sandpaper to arrive back at a gloss finish. I dread working the sides, as they contain the most brush lines, and I don’t yet have a proper method to secure the guitar to the workbench to address the side sanding and buffing. I’ll either work on my lap, or build a vise like the one shown here.

I still have the issue of the chip out on the headstock to resolve, but haven’t come to a good conclusion.

Here’s where I resist my desire to cut corners or give up. I need to work in phases, making small accomplishments in the finishing process, and get to the point where I can move on to the mounting of the bridge and the string setup. I’m so close.