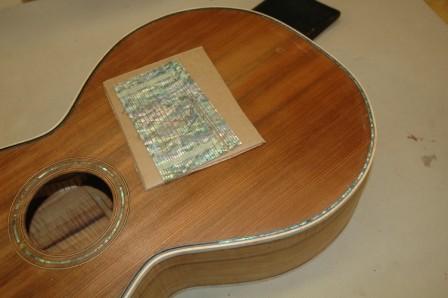

Guitar 906 – Oooh it is looking good

December 3, 2009

The inlay is looking really fine. After the epoxy dried, I was able to start sanding down to see the eventual end product. Here’s the headstock.

The fretboard needed lots of sanding.

The result was quite nice.

Put together, you can imagine what the end result might look like.

Carl asked me about the issues with the fret slots after the insertion of the inlay. Yes, it is an issue, but I laid out the inlay so as to avoid as many fret crosses as possible, and to align the leaves at the appropriate frets. In the end I had to saw through the frets where they were crossed by shell. It worked out well, and I’m ready to install the frets.

Carl, are you there? I’m thinking of adding a little bit of additional inlay, but it may be a bit too self aggrandizing. Take a look at the following and let me know if you are ammenable to allowing me to self promote.

It might be too much to drill my initials into you fretboard, but I thought I’d ask.