July 8, 2008

I prematurely glued down the headstock veneer on the maple neck. I say prematurely as I purchased graphite rods to set into the neck, and the presence of the headstock veneer will make the channel routing all that more difficult.

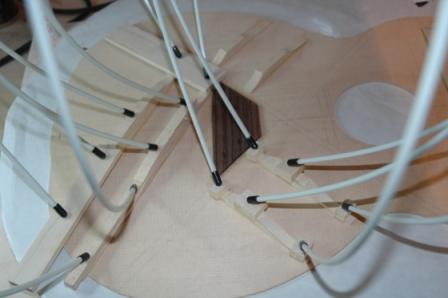

Maple necks are notoriously heavy and prone to movement or warping. The introduction of graphite rods (2, either side of the truss rod) will reduce the neck weight and give it stability to prevent future movement of the neck.

I’ll need to build a jig for sawing the slots before heading out to Vashon to use Carl’s table saw. Even with that, I will run short of the desired length of the slots, as I’ll run up against the headstock veneer. I’ll probably need to finish off the channels with my Dremel, which for a short distance, will work well.

My next challenge is routing out the tenon channel in the body and creating a matching tenon on the neck with the proper neck angle. O’Brien has a nice jig example, and I can apply the knowledge of setting neck angle from my ASL workshop.