August 19, 2009

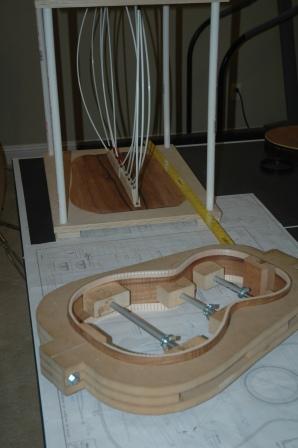

As 901, 902 and 904 cure (due date, August 30) I have started building guitars 905 and 906. Today, concentrated on 906 after drum sanding the side plates. Carl chose to change the top from Engelman Spruce to Sinker Redwood. I already had the redwood plates joined and thicknessed down to around .130″. I routed the channels for the rosette, installed, scraped down, then cut out the sound hole.

The following picture shows the Dremel tool and circle jig I use to route the channels and cut out the soundhole.

Koa bends very nicely. I thickness sanded down to around .100″ then bent side one, let it stand in the bender overnight, then placed in the mold.

Side 2 is bent and sitting in the bender until tomorrow morning, when I’ll remove it, cut the ends and place in the mold next to its’ brother and glue in the neck and heel blocks.

I have two opportunities for headstock veneers in Koa. I’ll let Carl decide which he likes best.

Also, Carl was looking for fretboard inlay with a vine design. Sent him some examples: